BUILD THE BACKBONE

Sovereign capability depends on delivering innovation at scale.

Deployable mesh antennas and structures used to be slow, expensive, and niche. Tendeg changed that. We design and deliver innovative mission-ready hardware on time and on budget. And now we’re scaling to deliver at the pace strategic proliferated systems demand.

All from Innovation Drive: our new, 160,000 square foot production hub in Louisville, Colorado. Purpose-built to serve the next generation of sovereign missions.

WHAT WE BUILD

Built for

the Mission

From small form factor Ka-band systems to large-aperture mesh reflectors, Tendeg builds antennas and structures tuned to your mission. From LEO, GEO, cislunar, and beyond, every platform is engineered for precision. Every system is built to deploy when it counts.

FLIGHT HERITAGE

Proven

on Orbit

We don’t just design antennas, we deliver them. 25+ deployable systems flown. 100% deployment and mission success. Trusted by Capella, NASA, Lockheed Martin, and more.

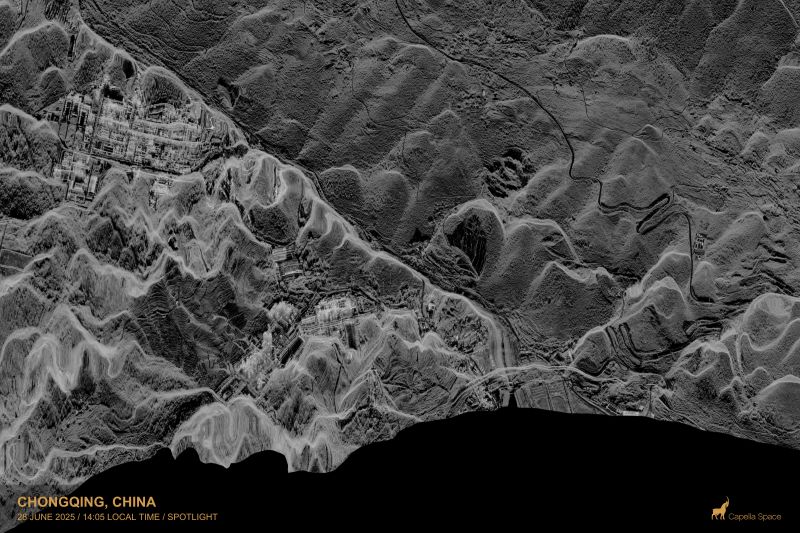

Tendeg has deployed 10+ high-precision deployable reflectors for Capella Space’s synthetic aperture radar (SAR) satellite constellation, enabling high-resolution, all-weather Earth observation.

Tendeg’s high-performance deployable antenna is enabling Lockheed Martin’s TacSat mission, ensuring secure, resilient, and reliable communications for tactical operations.

Tendeg’s deployable Ka-band antennas for NASA’s INCUS mission, enable precise cloud and storm system observations, providing critical data-gathering capability needed to improve climate models and enhance our understanding of extreme weather events.

Tendeg’s advanced deployable antennas for Astranis’s Omega-class bus, enable high-throughput communications in a compact satellite platform, supporting Astranis’s mission to deliver reliable, affordable internet connectivity to underserved regions.

HOW WE WORK

We Build What

Others Can’t

Space missions are accelerating. Threats are evolving. But legacy hardware timelines haven’t kept up.

Tendeg is built to change that.

We combine the precision and discipline of a prime with the urgency and adaptability of a startup: backed by smart tooling, modular architectures, and in-house test and integration.

This isn’t theoretical. It’s how we’ve successfully deployed over 24 antennas on orbit, and on mission.

The future won’t wait. We don’t either.

PROCESS

End-to-End Solutions

Tendeg manages the full lifecycle of deployable systems—design, prototyping, testing, integration, and delivery—all under one roof. Our process is technically rigorous, data-driven, and built to meet flight requirements without compromise.

1. Design

Engineer structures for mission-specific dynamics, packaging, and deployment.

2. Prototype

Build early models to validate clearances, sequence timing, and mechanical fits.

3. Test

Run thermal vac, vibration, and deployment tests in-house—replicating mission conditions.

4. Integrate

Final systems are qualified, verified, and ready to perform on orbit.

5. Deploy

Structures are proven in test, qualified for flight, and ready to perform on orbit.

NEWS

In Orbit and

On the Ground

From new flight deployments to factory milestones, Tendeg is building momentum. See the latest on our missions, innovations, and team.

SmallSat 2025: At a Turning Point

Tendeg Opens Purpose-Built Manufacturing Facility for Deployable Antennas

Capella Space Places Repeat Order for Twelve Large Deployable Antennas